Mode of Action of the refrigerating plant

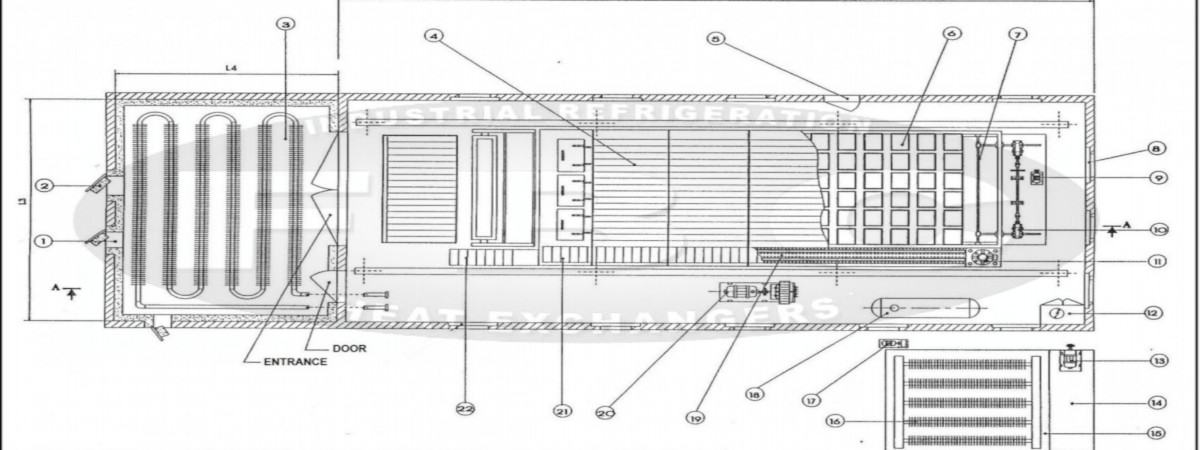

The compressor draws the vaporous refrigerant from the evaporator installed in the brine tank, compresses the same and delivers it to the condenser via an oil separator. Here, the heat extraction and thus, the liquefying of the refrigerant take place.

Between the condenser and the evaporator, there is installed the refrigerant flow control device which insures the supply of the liquid refrigerant to the evaporator, expansion takes place at the same time. The low pressure generated in the evaporator causes the evaporation of the refrigerant at low temperature and thus, the cooling of the brine. The liquid separator being mounted between the evaporator and the compressor prevents liquid refrigerant from being drawn in by the compressor.

The refrigerating plant has the function to cool the brine contained in the brine tank, while the brine in turn cools the ice cans filled with water. The brine temperature is limited to a given value by a minimum value electric thermometer witch is placed in the brine. The brine is circulated by the action of vertical agitators.

The ice can frames are made for holding and carrying more than one ice cans. Each wheeled frame is capable of holding 10 to 22 ice cans having a capacity of 25kg each. With the aid of a special circuit, the water in the dip tank may be heated in order to reduce the thawing time of the ice blocks.