ICE STORAGE is widely used in the Food Industries, Wineries, Air conditioning and in many other industrial refrigeration systems for over than 50 years. The principle of its operation is based on the generation and storage of the cooling capacity during the off peak energy requirements.

BASIC FEATURES

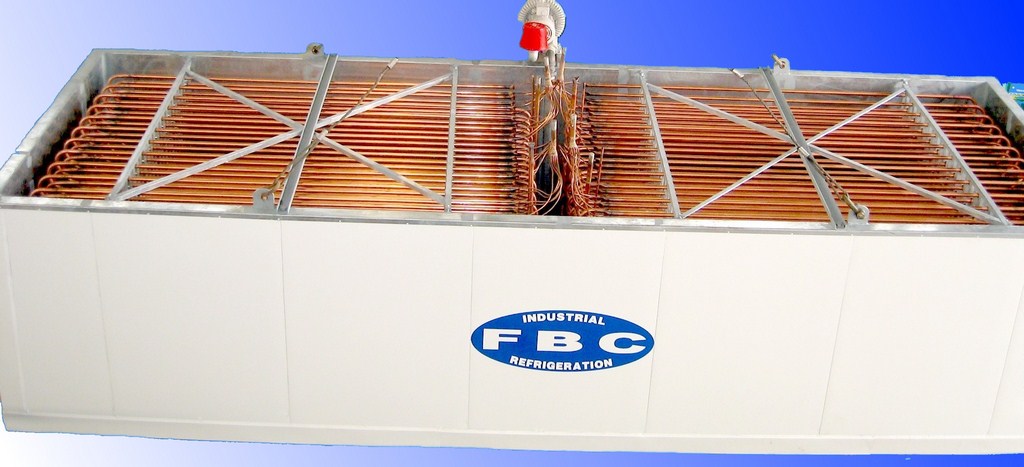

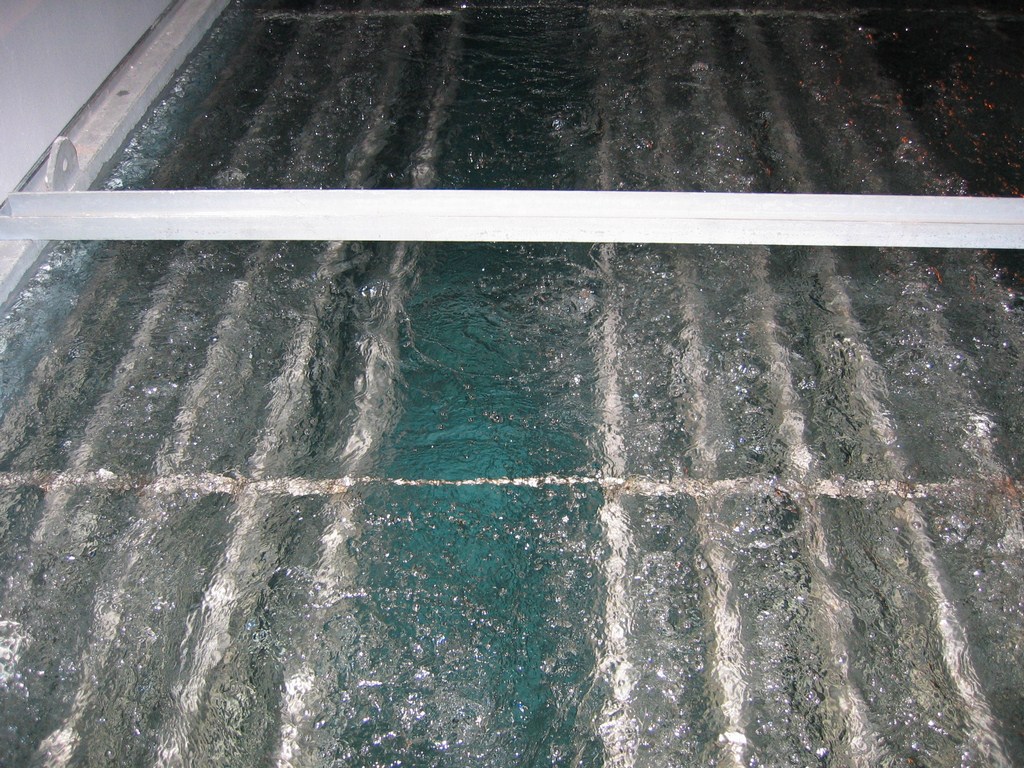

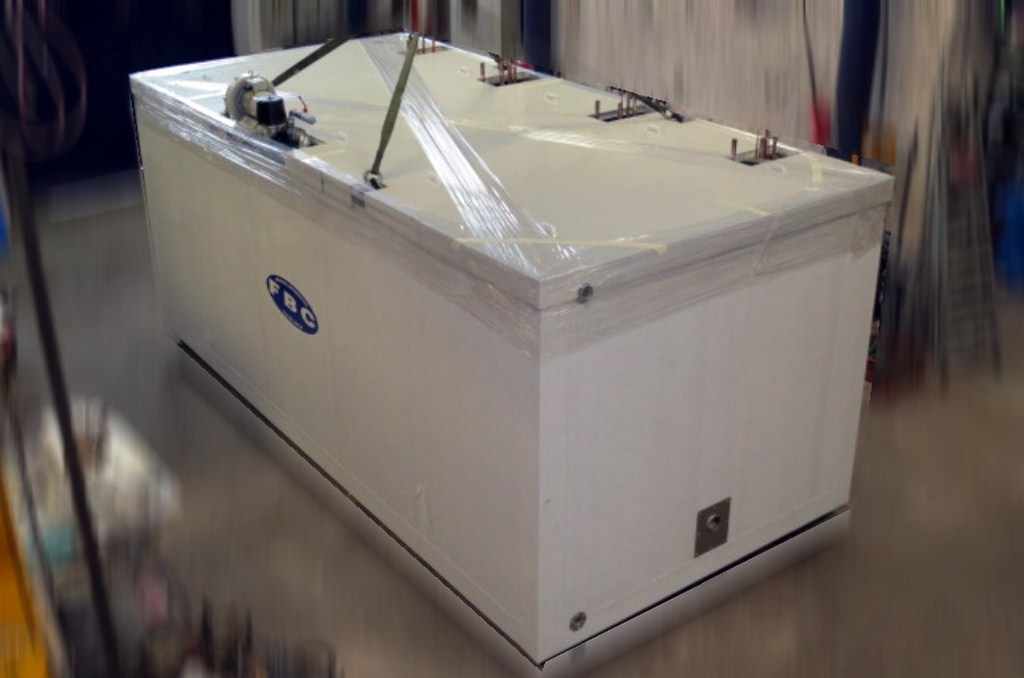

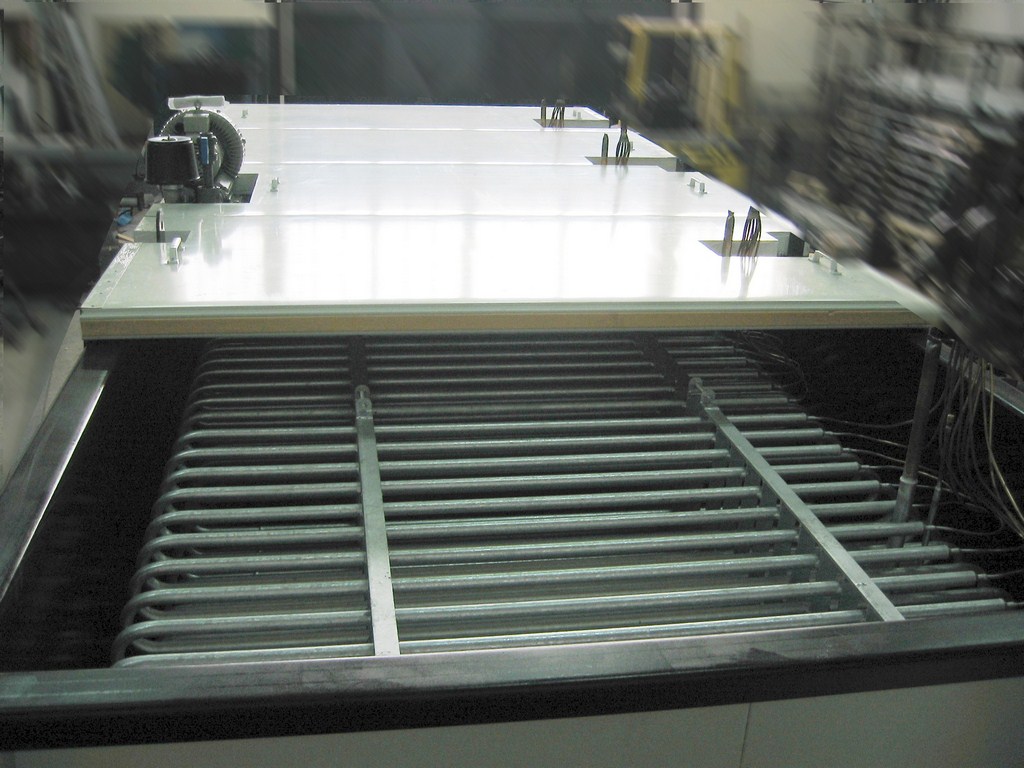

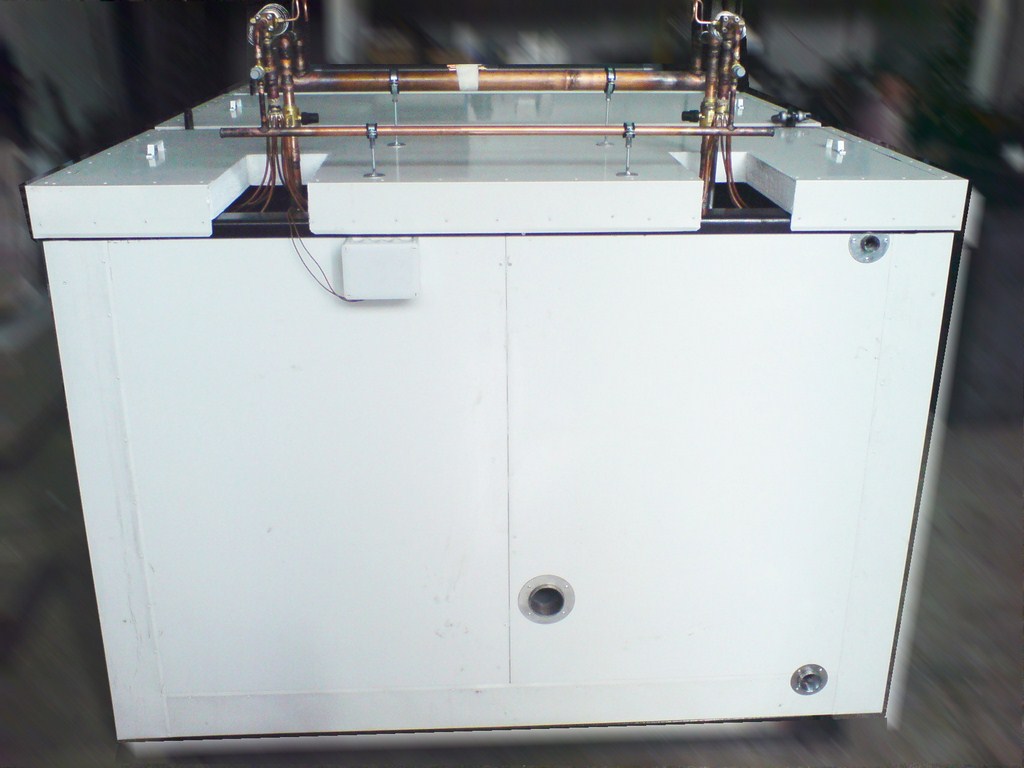

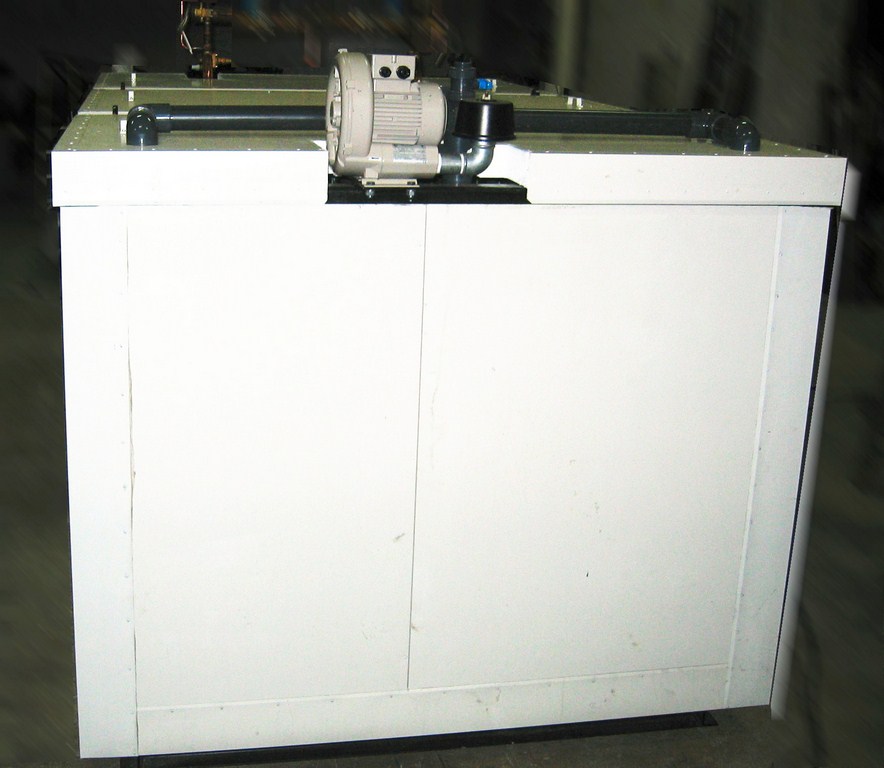

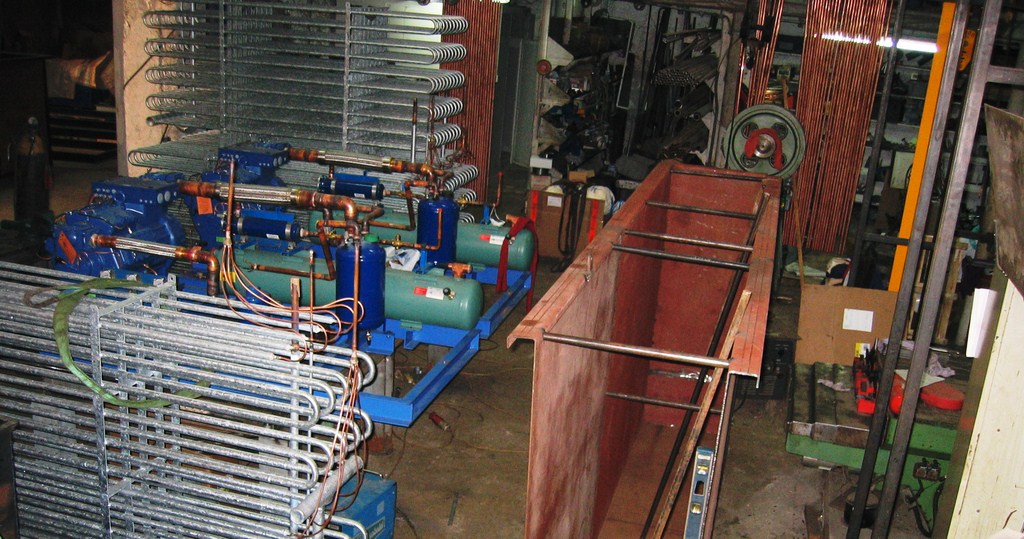

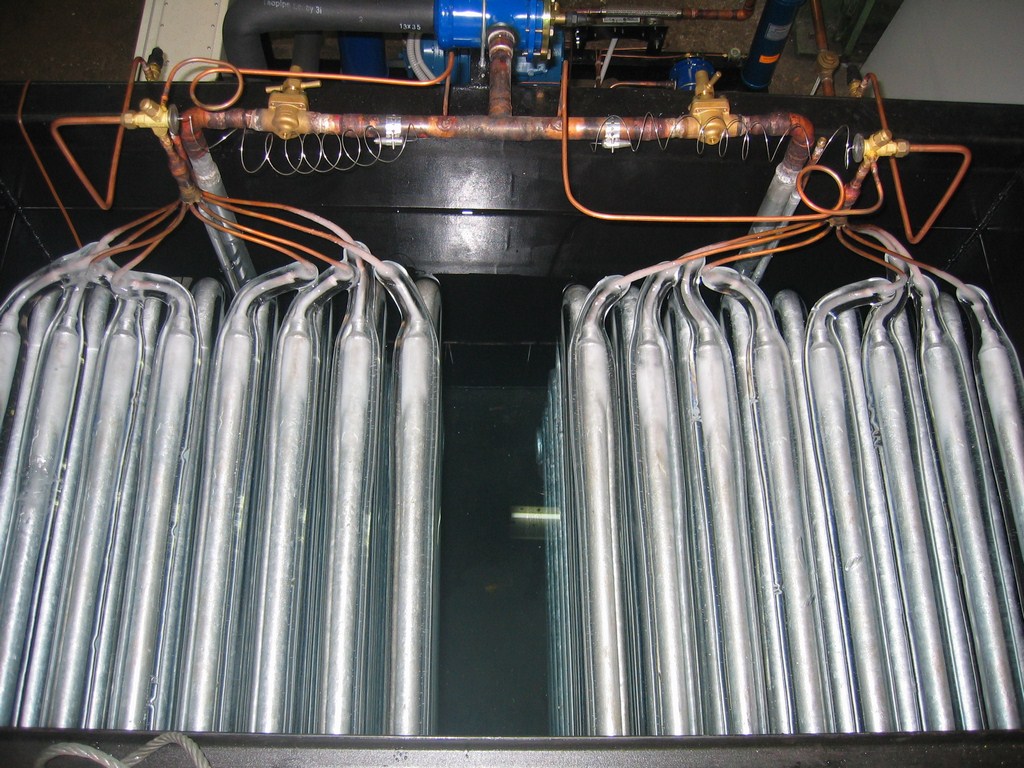

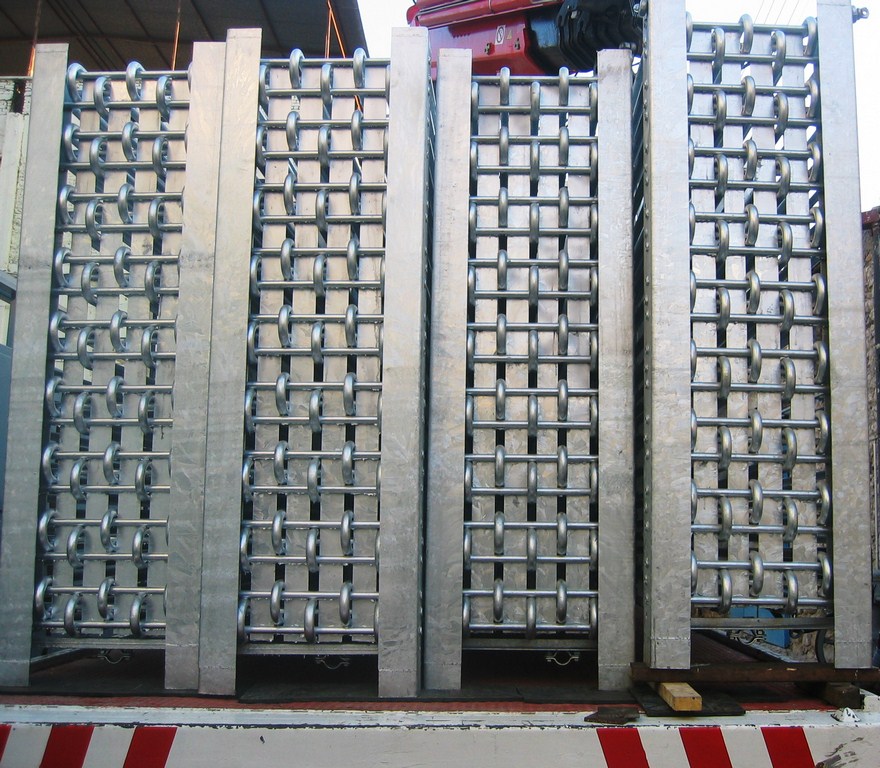

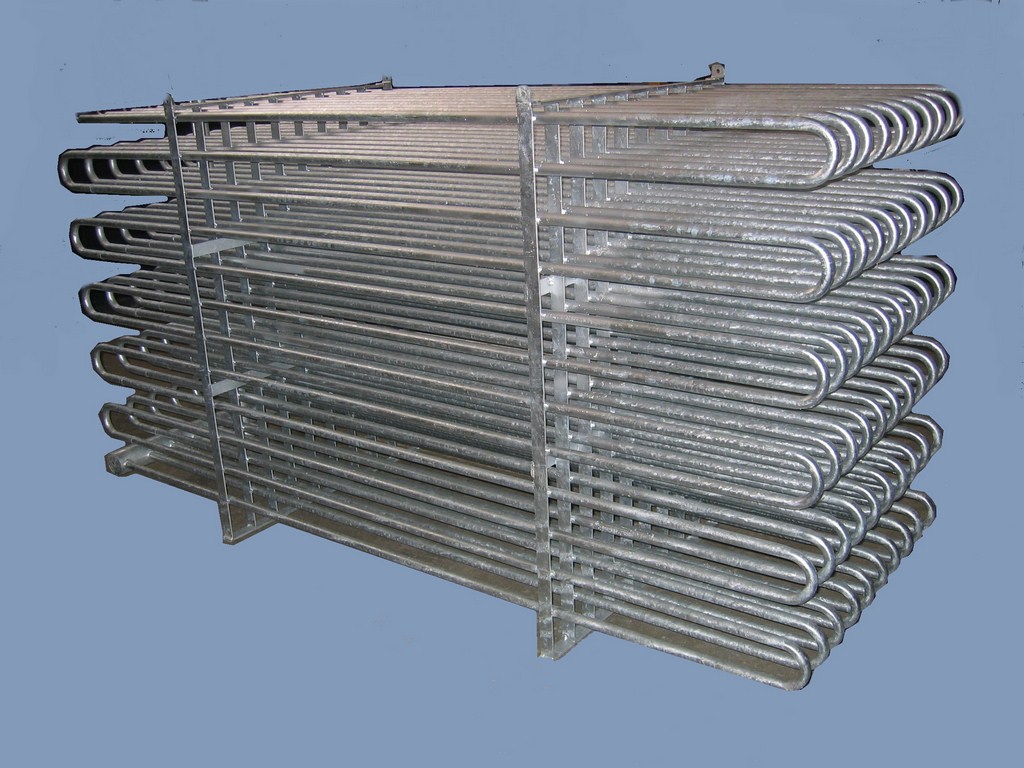

The main part of the ice storage is a tank which can be constructed in various dimensions depending on the refrigeration requirements. It is manufactured from steel sheets or in certain cases from armed concrete and it is peripheral insulated. The internal coil is made of hot deep galvanized steel tubes or copper tubes or stainless steel tubes. The water circulation can be succeeded either by using agitator or by air pumps. The refrigerant which can be used is Ammonia, Freon or Propylen Glycol Solution.

APPLICATIONS

Ice Storage is the ideal solution for supplying cooling water in temperature 0°C~+1°C.

A few examples of their usage are:

- In the Milk Industries and the Milk Collection units: in the process of pasteurization.

- In the Poultry Industries where the required chilled water is not constant but fluctuates depending on every day’s requirements.

- At the Plastic Industries: for cooling the mouldings and the products during the process of manufacture.

- At the Confectionary raw material Industries where a great number of different goods are produced and require different refrigerating consumption at different time periods with different refrigerating loads.

- Also in Air Conditioning for large buildings where the refrigeration requirements are temporally certain or fluctuate asynchronously e.g.: offices, factories, hospitals, hotels, gyms e.t.c.

BENEFITS

- Low electric consumption due to its operation during the off peak periods

- The compressor needs 50% lower capacity than an equivalent for operation with shell & tube exchanger because it operates for storing energy and not for direct demand.

- The temperature and humidity control is much more easier since the water temperature is always +1°C.

- Problems due to low evaporation temperatures, which can be destructive for a shell & tube or plate exchanger, do not exist here.

- The vaporization of the water circuit is much more easier and simple since the circuit is open.

- The large water capacity makes the Ice Storage also function as an inertia vessel.

- In new building the cost of piping and fan coils is lower than a simple exchanger since the water is always +1°C.

- The capacity can be easily increased and used for future loads simply by increasing the operating time of the compressor unit.

- Ice Storage’s life time is Unlimited since all the parts that it is composed of can be replaced.

- The cooling circuit can be divided in two or in more parts for autonomy and reliability.

The only disadvantage of Ice Storage is that it takes bigger space than a shell & tube or plate exchanger.

|

MODEL |

STORAGE CAPACITY |

BLOWER |

INT. DIAMENSIONS mm |

WATER VOLUME |

|||

|

|

Kwh |

Kcal |

Kw |

L |

H |

W |

m³ |

|

A8 |

120 |

103.181 |

CL 40 / 1.1 |

980 |

1900 |

2200 |

4,00 |

|

Α10 |

155 |

133.276 |

CL 40 / 1.1 |

1150 |

1900 |

2200 |

4,80 |

|

A16 |

240 |

206.362 |

CL 40 / 1.1 |

1750 |

1900 |

2200 |

7,30 |

|

A20 |

310 |

266.552 |

CL 40 / 1.1 |

2150 |

1900 |

2200 |

9,00 |

|

A24 |

360 |

309.544 |

CL 40 / 1.1 |

2650 |

1900 |

2200 |

11,00 |

|

A30 |

465 |

399.828 |

CL 40 / 1.1 |

3200 |

1900 |

2200 |

13,30 |

|

A32 |

480 |

412.725 |

CL 40 / 1.1 |

3500 |

1900 |

2200 |

14,60 |

|

A40 |

620 |

533.104 |

CL 50 / 2.2 |

4250 |

1900 |

2200 |

17,70 |

|

A48 |

720 |

619.088 |

CL 50 / 2.2 |

5210 |

1900 |

2200 |

21,70 |

|

A50 |

775 |

666.380 |

CL 50 / 2.2 |

5300 |

1900 |

2200 |

22,10 |

|

A56 |

840 |

722.269 |

CL 50 / 2.2 |

6000 |

1900 |

2200 |

25,00 |

|

A60 |

930 |

799.656 |

CL 50 / 2.2 |

6350 |

1900 |

2200 |

26,50 |

|

Α64 |

960 |

825.451 |

CL 50 / 2.2 |

6950 |

1900 |

2200 |

29,00 |

|

Α70 |

1085 |

932.932 |

CL 50 / 2.2 |

7050 |

1900 |

2200 |

29,20 |

MODELS

FREON OPERATION