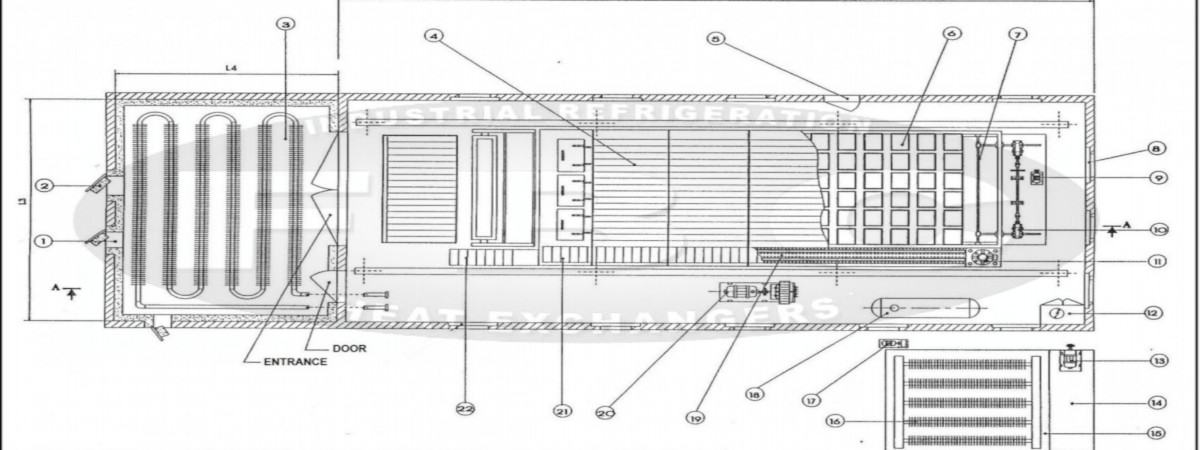

Description of the main parts of an Ice Block Plant

1. COMPRESSOR

The refrigerant compressors that are used function according to the counter flow principle with single-stage compression. Depending on the Plant’s size the compressors are arranged in either reciprocating or screw compressors. The drive of the compressor is accomplished either by pulleys or slip ring rotor motors, depending again on the plant’s size and the local conditions. The process of monitoring and safety equipment is clearly arranged directly on the compressor.

2.REFRIGERANT FLOW CONTROL DEVICE

-For operation on Freon

It is used a thermo-expansion or an electronic valve and electromagnetic valve which takes command from the electronic thermostat.

-For operation on R-717 (NH3)

It is used flooded system with a liquid level regulator, for safety, and also an electromechanical float switch. Electro-valve takes command from the electronic thermostat and the electromechanical float switch.

3. TUBE TYPE EVAPORATOR

Tube-type evaporators are used for NH3 or Freon refrigerants as they ensure favorable overall coefficients of heat transfer.

The evaporator comprises several evaporator elements. These elements are connected by a header at the refrigerant inlet and outlet ends in such a way that one or two evaporator groups are formed. The evaporator groups are connected with each other, so that a uniform liquid refrigerant level is guaranteed in humid situation. The evaporation temperature is approximately 6°C less than the temperature of the brine to be cooled.

4. LIQUID SEPARATOR (for NH3)

The liquid separator is mounted above the evaporator and it is designed as a vertical or horizontal tank. It is used for separating the liquid refrigerant particles possibly entrained from the evaporator. The return of the separated liquid to the evaporator is guaranteed by a line sloping downward. The injection of the refrigerant proceeding from the refrigerant flow control device is accomplished via this downward line, too.

5. EVAPORATIVE CONDENSER

The heart of the compressor is the galvanized steel element -in which the refrigerant liquid is circulated-cooled and from hot gas becomes humid. There exists a closed cooling water circuit which is maintained by a re-circulating pump. In the evaporative condenser the water is cooled due to the evaporative cooling effect and re-used for liquefying the refrigerant. This achieves lower condensation pressure with result the lower electric consumption.

6. AIRCOOLED CONDENSER (ONLY FOR Freon)

It is used either to reduce the water consumption to a small percentage or if there is not sufficient fresh water for the supply of a shell-and-tube condenser

7. WHEELED FRAMES FOR ICE CANS & ICE CANS

The wheeled frame ice cans are metallic frames into which 10 to 22 ice cans can be fitted to each one, depending on the size of the plant. Each frame is equipped with casters on either side & bocks are provided for the suspension from the crane beam. The ice cans are sheet metal tanks of rectangular cross-section tapering downward. They are covered with an anti-corrosive coating.

8. BRINE TANK

The brine tank contains the brine. Furthermore, it accommodates:

- Tube type evaporators

- Vertical agitators

- Frames with ice cans

- frame feed mechanics (On request)

For the protection against refrigeration losses, the tank is provided with a wooden cover or thermal panels. The walls and the bottom have to be covered by insulation.

9. AGITATOR

In the brine tank there is mounted an agitator of corresponding capacity. It is used for stirring the brine within the tank. Furthermore the brine tank is provided with corresponding elements built in for the agitators. The circulation of the brine by the agitator fosters the cold transfer from the evaporator to the brine and ice cans.

10. ICE CAN DIP TANK

The thawing tank is a sheet metal tank. It is designed in such a way that it can accommodate one ice can frame at a time. For reasons of water economy, stops are provided which prevent the ice can frame from being submersed. In order to reduce the thawing time, the water in the thawing tank is constantly pumped through the heat exchanger by a re-circulating pump, where it is heated by the hot compressed gases. Besides, this tank is provided with water inlet and outlet ports.

11. ICE CAN FILLER

This is a tank with filler pipes according to the number of ice cans in the ice can frame. This tank is filled with water which flows into the empty ice cans via the filler pipes when turning the tank. The tank is dimensioned in such a way that it can accommodate just a quantity of water being necessary for the filling of one set of ice can frame. Depending on the building conditions, the ice can filler can be placed on a bracket which is mounted to the ceiling or to the crane track. Operation is effected manually.

12. ICE BLOCK DUMP TABLE

This is an inclined wooden plate provided with a flange at the bottom end. The ice blocks sliding out of the ice cans during the tipping slip onto the dump table.

13. ICE CAN FRAME TIP

The above-mentioned ice can dip tank is provided with the ice can frame tip. The tip is used for supporting and tipping the ice can frames. When tipping the ice can frames, the ice blocks being thawed from the cans slide out. The handling is effected with the aid of the ice crane.

14. ICE CAN FRAME FEED MECHANISM (upon request)

Once started the feed mechanism pushes the ice can frames forward. They are moved until another ice can frame fits into the empty space when withdrawing the drive system. The ice can frame feed mechanism is driven by a geared motor and a reduction gearing through a leverage.

15. ICE CAN FRAME CRANE WITH BEAM

A floor-controlled crane with two rope drums is running on rails which are mounted on a crane frame. The two ropes are connected by a beam to which the ice can frames are hung. The crane is used for handling the ice can frames. A control panel contains the corresponding push buttons for the hoisting and crane traveling mechanisms.

16. GANGWAY

A gangway is provided near the liquid tank. From the gangway it is possible to operate the crane and the ice can frame feed mechanism.

17. ELECTRIC SWITCH GEAR ASSEMBLY

The electric switch gear assembly contains the essential switch gears and monitoring read-outs for the control and operation of the system.

18. COOLING BRINE

The cooling brine has to fulfill the following demands:

- No contamination by foreign matter (e.g. oil, etc.)

- Indifferent to metallic materials

- A lower cooling limit at least 15°C below the average working temperature.

The technical data and the way of construction of the Ice Block Plants, are always under upgrading and improvement for their perfection and completeness.