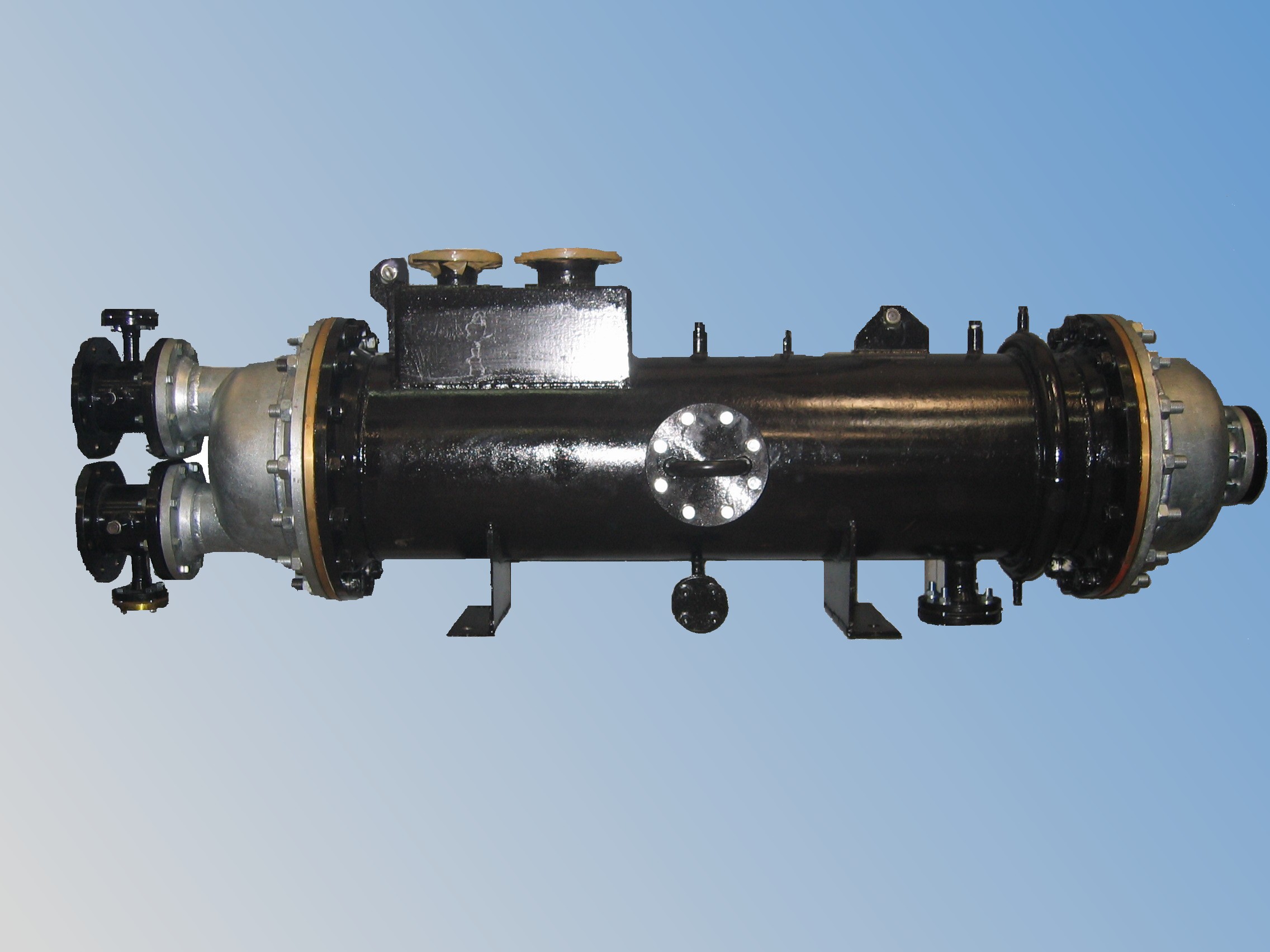

The EXCHANGERS we study, design and construct in FBC have a wide range of use in all procedures of production in Industries and Navigation.

They are also the main application in heat exchange / heat convection among fluids, incompressible (liquids), compressible (gas, steam).

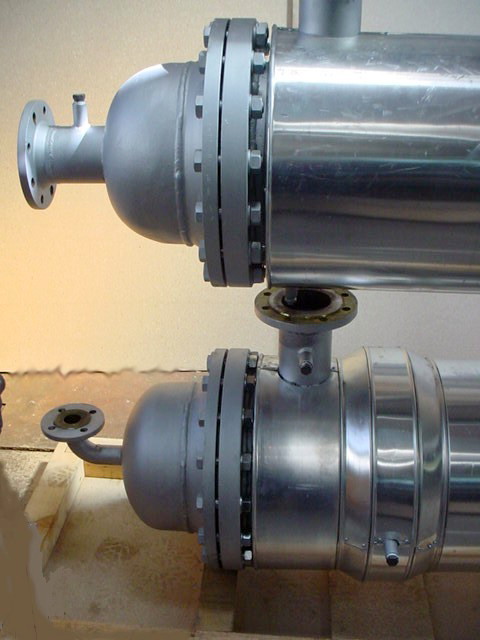

FBC has the skill and the experience either for replacing an existing Heat Exchanger with improved efficiency or for studying, designing and constructing a new one upon request always in cooperation with the customer.

The Exchangers according to their usage enlist as below:

1. HEATERS (Oil Heaters, Water Heaters, Fuel Heaters, Electric Heaters e.t.c.)

2. COOLERS (Water Coolers, Air Coolers, e.t.c.)

3. EVAPORATORS (Freon Evaporators, Ammonia Evaporators, e.t.c.)

4. CONDENSERS (Steam Condensers, Freon Condensers, Ammonia Condensers, e.t.c.)

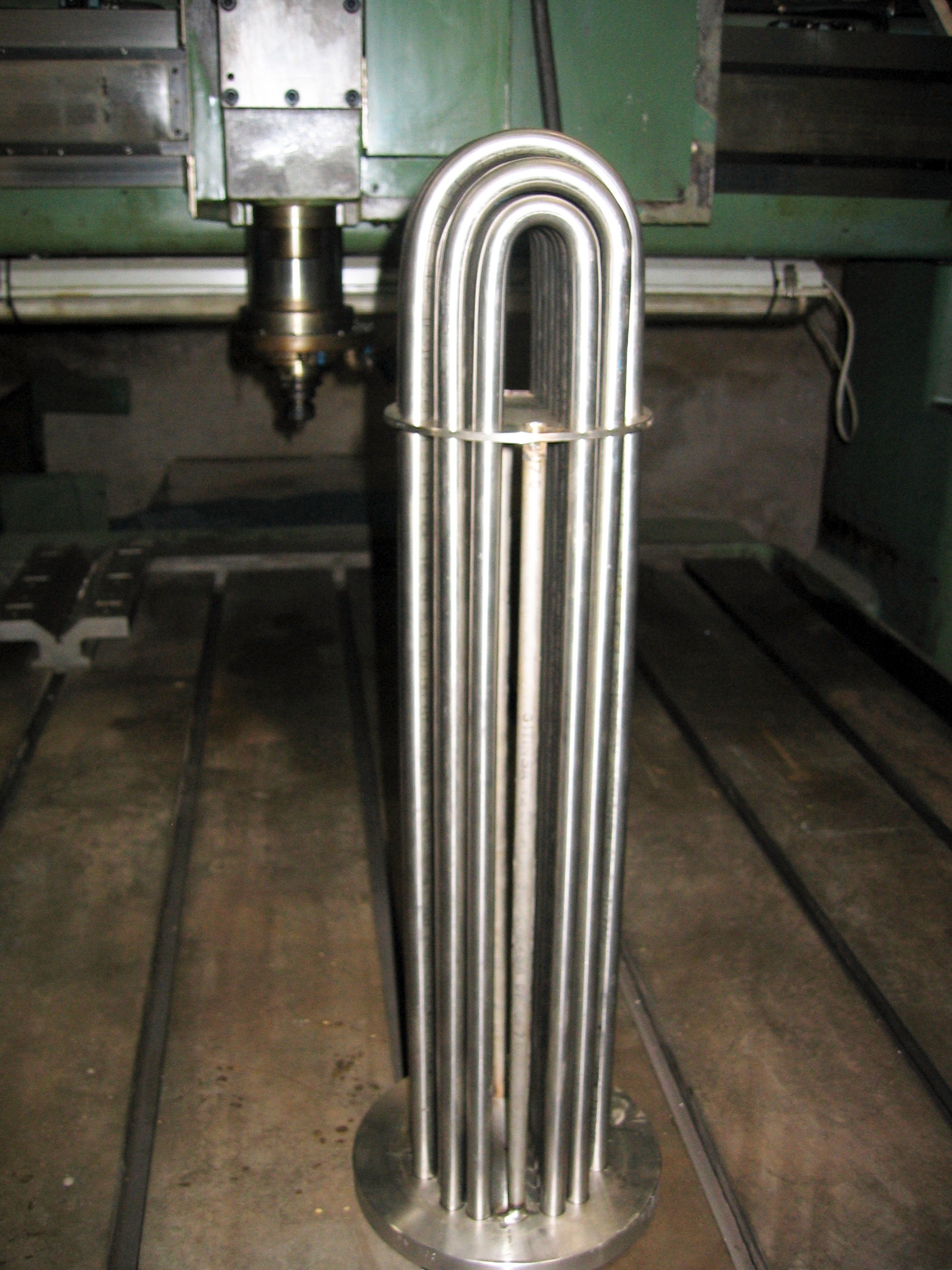

Also they enlist as Shell, Tube and Plates.

In FBC, every Heat Exchanger we build meets and exceeds the level performance and that accomplishes by increasing the exchange surface by using various methods we learned from our experience.

HIGH QUALITY

Every Heat Exchanger is fully tested before delivery to ensure high quality and performance according to standards and all the requirements and expectations of our client.

CHECKING as

optical

dimension

radiographic

dye-penetrate

hydrostatic

are always in accordance to standards.

All the materials for Heat Exchangers are purchased from reputable and reliable mills either from Inland or other European countries, fully certificated.

Mill certificates are always available to our client upon request.

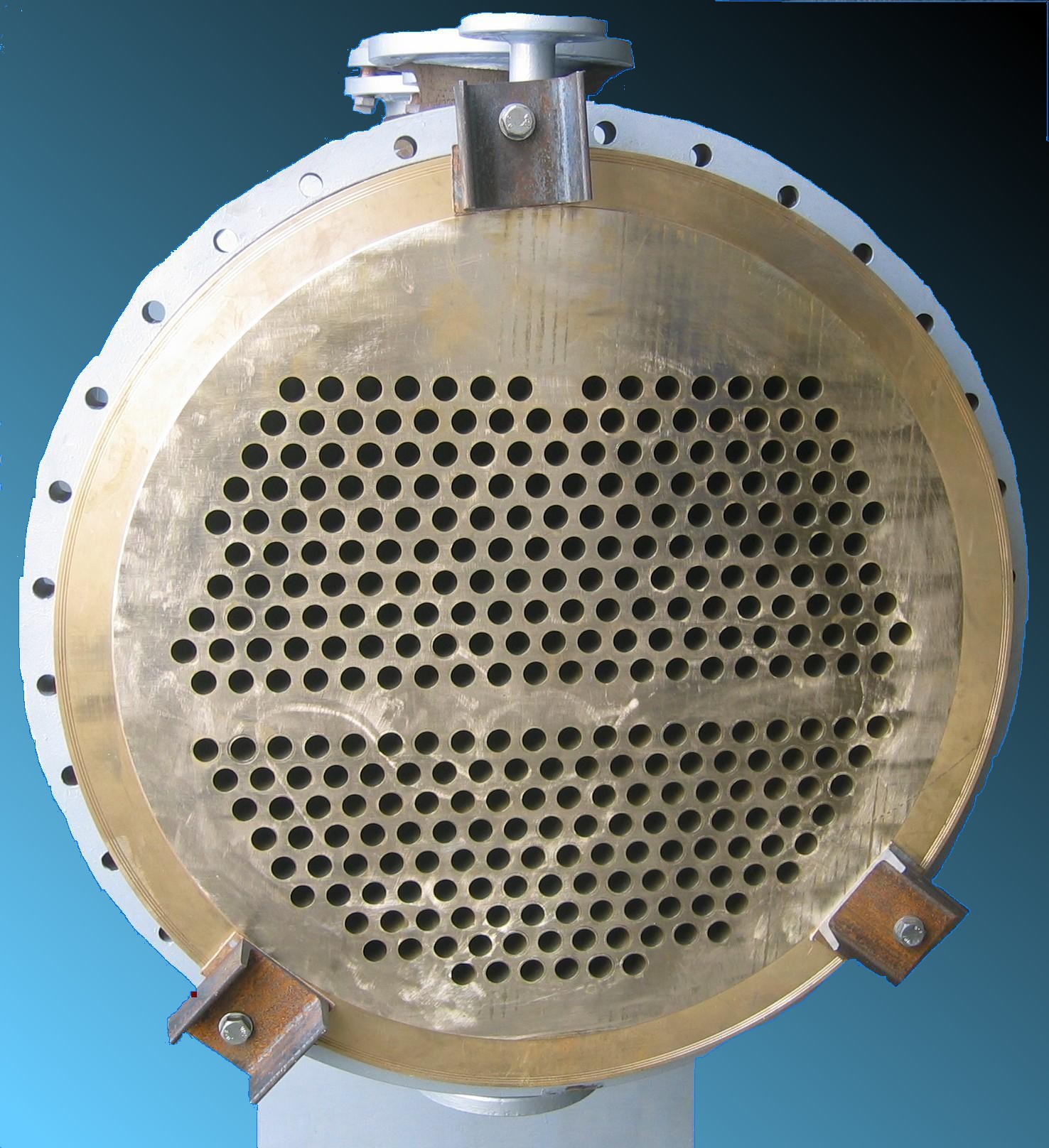

All Heat Exchangers, before delivery, are sealed on tube plates according to test data and the standards

The use of latest technology for tube plates drilling re-tubing and expansion minimizes the human error and guarantees high quality and performance.